i’m leaving my 3 million dollar boiler room to two guys who said “trust me”

We were called into a large meat plant processing facility in Columbus, Ohio. The mission was simple: find out what’s wrong here, and they knew a lot was wrong, and start fixing. The facility had 2x 300HP boilers - VaporPower- and 2x cooling tower systems.

We could not find a single system without multiple problems, and as one problem was fixed, another revealed itself.

The boiler’s blowdown valves were operating, but no water coming out. This led to conductivity being greater than 10,000 microohms, well above the field limit of handheld sensors. The previous water treater had continuously increased the blowdown on the controller but failed to actually look at if water was coming out. There was heavy scaling both surface drum and bottom blowdown on the boilers, thus no water. We were able to figure out the only blowdown that these boilers were capable from was the sample port.

We’re pretty handy, but we we’re not pipefitters. We grabbed some pipes and put a makeshift blowdown together from the sample ports. Yikes. Onsite engineering was skeptical. They were told problems were stemming from the softener malfunctioning and various other issues inside the actual plant such as beef product returning in their condensate. We dialed it down to the very basics “this boiler needs blowdown, and here’s the only way we have at the moment before getting some pipefitters on here. Failure to do this is going to lead to a shutdown in the next 2 months.” (The client later admitted they were on rental boilers a few months previously from scale problems)

The client, with a healthy dose of skepticism figured why not, I’ll give them overnight of blowing down from a sample port to see if this works. The results were far better overall water quality in the boilers, and conductivity back down to a proper range (under 5000)

Later we found out he figured to himself “I’m leaving my 3 million dollar boiler plant to two guys who are blowing down from a sample port”

Boiler water- this was day two after finding the sample port was the only available blowdown in the boilers

The cooling tower feed and control system had every problem imaginable

Multiple pumps programmed incorrectly AND not feeding any chemistry

Bleed was shut off on one of the systems as the bleed was going to a clogged drain which flooded a room

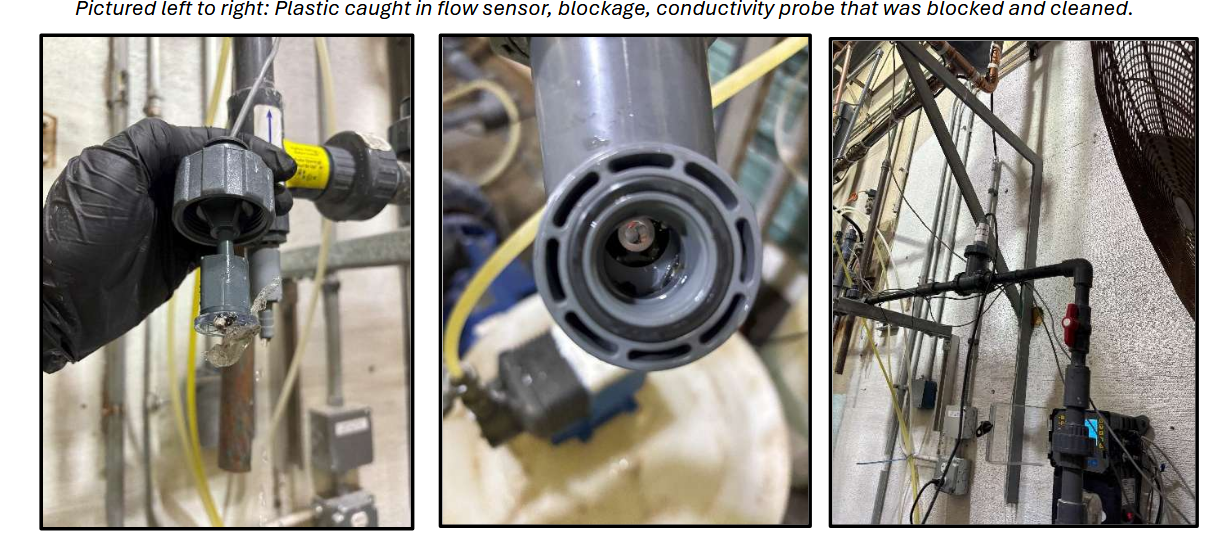

Clogged PVC lines which had both simple debris and scale

Injection quills which needed replacement

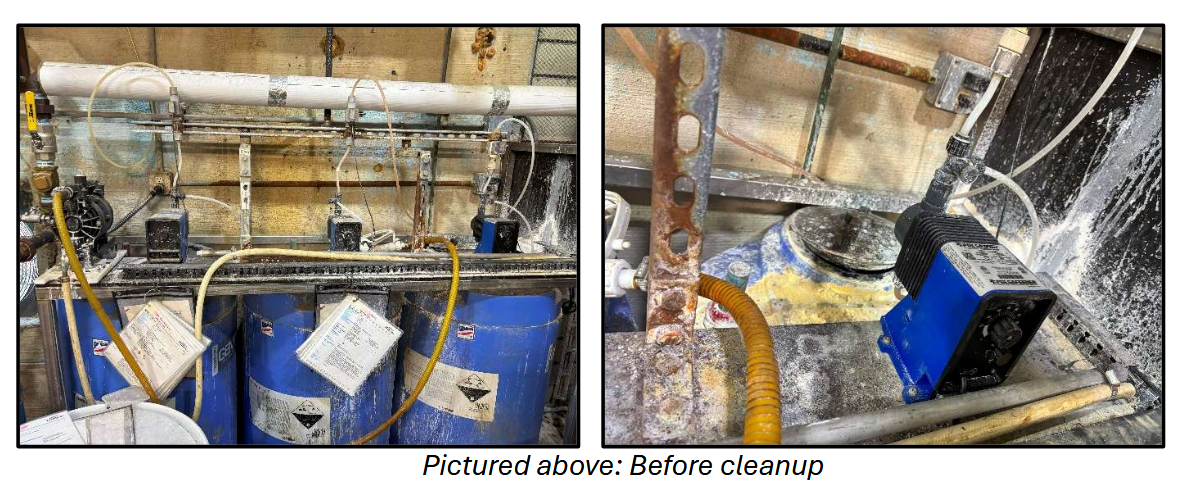

Little to no organization or attention to cleanliness or safety. Spilled chemistry was everywhere.

Blocked chemical feed tubing

It was a lot of hands on cleaning, reworking some PVC, cutting new lines, and replacing out broken injection quills.

Finally, the boiler feed tanks were unpresentable, to say the least. It’s often not thought of, but dried chemical presents a very unsafe work environment. The chemistry often has various skin irritants and can cause chemical burns, along with reactions if another chemical spills on top of it.

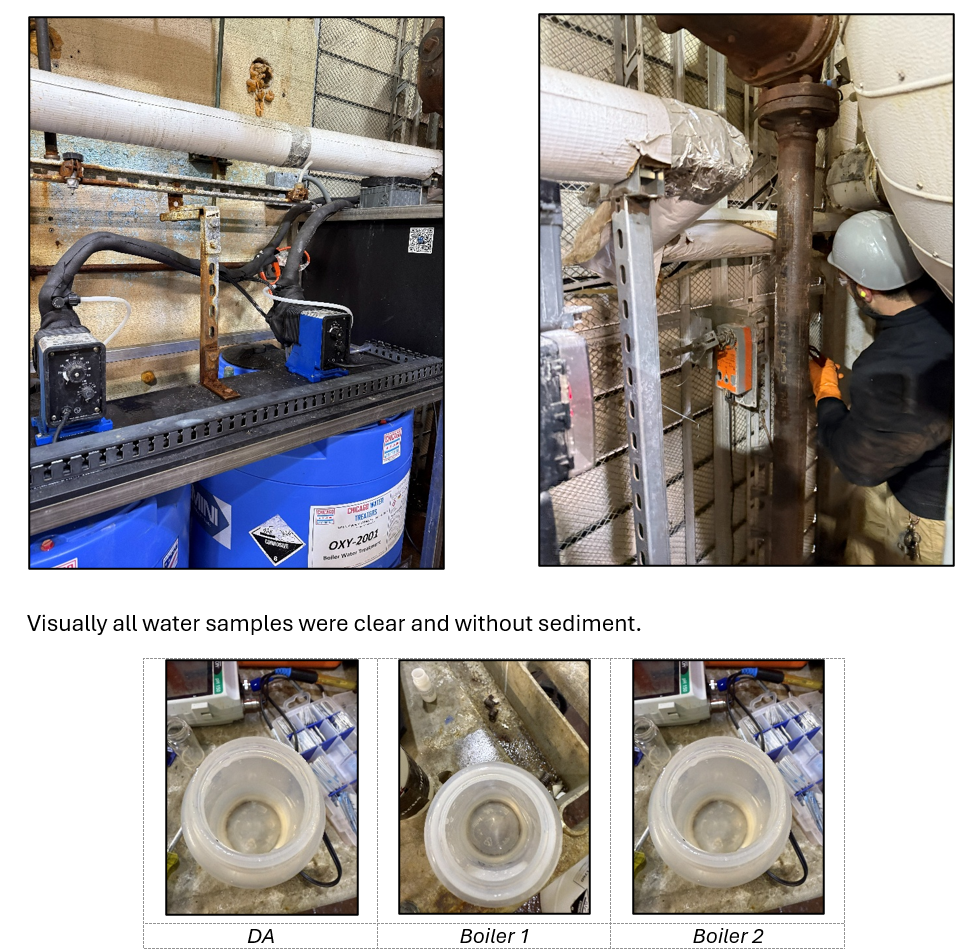

Now we see a lot of “new installs” on linkedin and various other platforms. I always like to say, the easy part is a clean install. The tough part is keeping it clean. Here’s a few pictures from the last service report. It’s taken more work. We find there’s still more problems that present themself. At this latest one, I needed to climb up in between the DeAerator and replace out an injection quill that seemed to be working, but didn’t just sit right with me. I was right- it was priming but had an incomplete clog which meant a little chemistry got through, but not the dosage that would be expected based on the timing we set on the controller.

So there you have it. It took a lot. It wasn’t just chemistry knowledge. It was applications knowledge.

Having total understanding of how these systems are supposed to run, how each component can fail, and how to fix it were all critical to getting this facility back on track.

Over time, the boiler’s original blowdowns all freed up. The softener works fantastically and was never an issue. We were able to use the existing previous supplier’s chemistry up and order our chemistry in without any hiccups and using the same equipment, which saved the client potentially thousands. The boiler’s runtime has not gone down, which was a frequent issue before.

As a preventative measure, they were running acidic cleaning through every month. They don’t need to do that anymore, and their boiler inspector commented it’s one the cleanest they’ve seen.